Commercial Roofing

Georgia Roofing & Repair, Inc., located in Atlanta and Alpharetta, is a commercial roofing company that specializes in roof repair, maintenance, and replacement services.

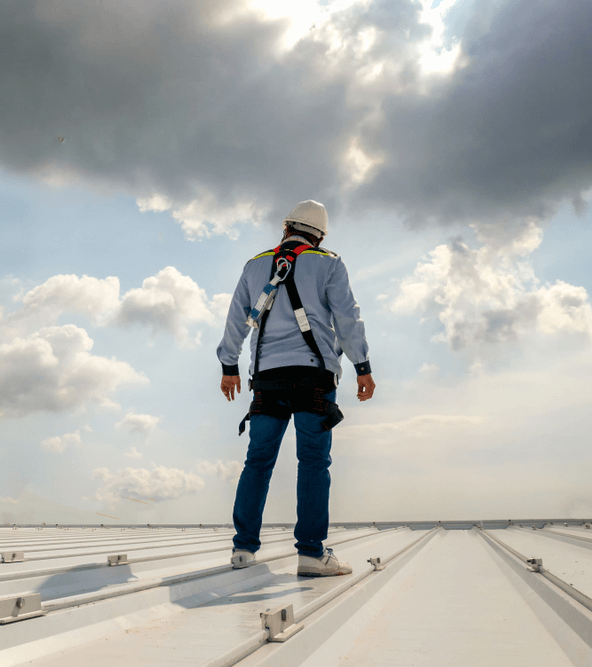

In addition, we also offer commercial roof inspection services for prospective new buyers or existing landlord owners. Roof inspection services include digital photography and an overall evaluation report.

GA Roofing & Repair, Inc., provides only the best in commercial roofing installation and manufactured supplies for your flat roof system.

We’re certified by all major manufacturers for TPO, EPDM, PVC, BUR, Modified Cap Sheet, and Elastomeric single-ply membrane. All manufacturer installation guidelines are followed from beginning to end. Manufacturer and labor warranties are always provided upon 100% completion.

Our installation methods and materials have been well-tested and proven for efficiency to save our clients time and money.

Atlanta Commercial Roof Repair

Most commercial roof systems in Atlanta, GA. are designed to be flat or low sloped and will require roof repairs and ongoing maintenance throughout its useful lifespan. GA Roofing & Repair, Inc. is well known for its Atlanta commercial roof repair division and highly trained technicians that will inspect the entire roof surface for noticeable signs of damage and/or preventative maintenance. We work quickly to resolve any issues such as excessive standing water or cracks that may have resulted in a roof leak. From a small to large commercial roof repairs, there is no better company than us to handle the job.

In fact, after repairs and maintenance have been completed we can also offer a complete a roof tune-up. This will help future leaks from popping up in other areas of your flat roof system that may beginning to show signs of aging.

Commercial Roof Replacement

If your commercial roof is over 20 years old, it maybe time to replace. Your hard earned money is not spent wisely chasing leaks on an outdated commercial roof system. GA Roofing & Repair is the #1 rated commercial roof replacement company located in Alpharetta and Atlanta. We’ll advise you the most cost effect long-term low maintenance approach available. Our highly trained team will provide a timely and competitive quote for a roof replacement system best suited to your needs. Your place of business is our business too, and without a quality commercial roof, you can’t operate as needed. Therefore, call GA Roofing & Repair and get your new commercial roof or existing roof repaired today!

A new commercial roof is a significant investment. The roof over your head is, above all, one of the most important features of any commercial building. It’s the key to keeping your business open and especially operating. You, your customers and employees come first, keep everyone safe from the weather. A secure roof also helps keep insects and other intruders out; as well as, increases the efficiency of your commercial HVAC systems.

Commercial Roof Inspection

At GA Roofing & Repair, we understand just how important a properly functioning commercial roof over your head is. We are industry leaders of high-quality commercial roof leak preventative maintenance and commercial roof inspection services. As a result of decades of hands-on experience, we’ve become very good at identifying roof issues before they become a problem. We provide our clients with a hands on approach and budgeting for roof repairs, preventative maintenance, and new roof installation. We know how to not only diagnose your roof, but fix it within a budget that works for you.

We’re trained to get the job done right the first time, and pride ourselves on thereby exceeding our clients’ expectations. Click on the links below to learn more about the commercial roofing systems we offer and service.

• Single-Ply Roofing

• TPO Roofing

• PVC Roofing

• EPDM Roofing

• Elastomeric Roofing (Metal Roof Coating)

• Modified Bitumen Roofing

• Built-Up “BUR” Roofing (Coal Tar Pitch and Asphalt)

• Metal Roofing Assemblies (Standing Seam, R-Panel, Flat Seam,)

• Multi-Family Roofing

WHAT IS A COOL ROOF?

Traditional roof materials and colors will absorb a lot of heat and solar energy, therefor making them stay hot. A cool roof is white, so it will absorb less solar energy, consequently keeping your home or building 50 degrees cooler during hot summers.

What are the BENEFITS OF COOL Commercial ROOF

• You will save a lot more money, and likewise spend less on energy costs.

• Feel more comfortable in your home, even as a result of running your HVAC units less..

• Elastomeric or white single-ply can usually be applied over your existing roof, meaning that you won’t need to remove your old roof, therefore saving you money and time.

• Save on HVAC equipment costs, as a result of not be running your equipment as much. Not only will you be using less energy, but you will also be saving yourself money as well.

• Additionally, you may be able to get qualify a roof coating as a building maintenance cost instead of a capital expense, which must be depreciated over time.

• Finally, you may be eligible for rebates from State Energy Commission or your local energy provider.

($0.15 per square foot or higher.)

Environmentally Friendly Roofing

In predominately colder regions of the US, darker roofs are the norm. Therefore resulting in heating up the home or building and benefiting from an increase in indoor temperature. In contrast, having a white roof in warmer regions will help keep your home or building nice and cool for the hotter seasons, resulting in a great deal of savings over time. Roofing waste has become a an additional problem in the US and has taken up 7% to 10% of landfill space in the past 40 years. As a result, Georgia Roofing & Repair makes the effort to reduce roofing waste in landfills by roofing over your existing roof system, if possible.

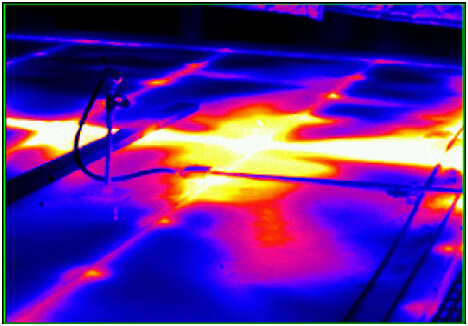

Infrared Moisture Inspection

Here at GA Roofing & Repair, Inc., we utilize our infrared roof moisture inspection service to prevent you from needing major commercial roof and interior repairs. Infrared thermography will help to identify temperature differences created by saturated insulation in the roof assembly. During the inspection, the problem areas are marked on the roof and also presented in a detailed report. Reports will then be confirmed using electric capacitance or nuclear tools. So rather than spending an enormous amount of money to replace the entire roof, using our infrared inspection services will help to identify and replace only the immediate problems that need to be fixed.

TPO Roofing – Thermoplastic Polyolefin

Thermoplastic Polyolefin TPO roof repair and maintenance is a must between every 5-10 years for top performance. TPO is probably the most popular and fastest-growing commercial roofing system available today. This roofing system is made of especially durable material that can certainly tolerate a wide range of temperatures. These roofs are exceptionally resistant to ultraviolet, ozone and chemical exposure.

GA Roofing & Repair can offer TPO roof repair and roof replacement services that feature high resistance to fire, punctures, chemicals and high winds. Noteworthy, TPO membrane, if properly maintained can be expected to have a lifespan of 20+ years.

PVC Roofing – Plyvinyl Chloride

Polyvinyl chloride PVC roof repair and maintenance is important as it is made up of thick, flexible thermoplastic material. PVC membrane is a highly resistant, versatile and durable option. Single-ply PVC membrane has become a very popular choice for Atlanta restaurants because of it’s roof grease trap resistance to damages. Restaurant and retail property owners have enjoyed the services we provide them for PVC roof repair and maintenance.

PVC roof systems are to install and can also be made to fit a flat roof. This system of roofing, while not as common as TPO and provide great protection when it comes to intense weather conditions, such as torrential rain, snow or ice.

EPDM Roofing – Ethylene Propylene Diene Monomer

Ethylene Propylene Diene Monomer, or in short EPDM roofing, will offer durability, versatility and added heat. , reasonably making it one of the longest lasting types of commercial roofs available. Commercial rubber EPDM roof repair systems are also typically easier to install, maintain and repair than most types of commercial roofs.

MB Roofing – Modified Bitumen

Modified Bitumen (MB) granulated cap sheet membrane roofing, if installed correctly, is a 2-ply system. Initially, a fully adhered base cap sheet underlayment is installed prior to MB granulated cap sheet. Similarly to multi-layered built-up (BUR) roof systems to create a weather-resistant surface. The difference between the two is the multi-layered asphalt bitumen adhesive. Modified Bitumen roof repair and maintenance, if done properly, can extend the lifespan of this type roof system 20+ years as specified.

The bitumen itself is waterproofing and an adhesive all in one. When combined with a substrate like Atactic Polypropylene (APP) or Styrene Butadiene Styrene (SBS), it will receive an increase in its low-temperature flexibility.

Mixing with (APP) will give the roof a plastic quality, therefore allowing the bitumen to stretch without breaking. Whereas (SBS) modified bitumen has a rubber quality that allows it to stretch, and certainly still be able to return to its original size afterward.

These stretching properties provide extra wear resistance in extreme weather conditions. Due to these properties, modified roofs have been a popular choice since their introduction in the 1970s and make commercial roof repair moderately easy.

BUR Roofing – Built-Up Roof

Built-Up roofing also known as (BUR) is one of the most expensive, oldest, and most reliable methods for installing a new roof today. This type roofing system is made by layering several plies of roof felts, made of bitumen-saturated fiberglass, polyester, other fabrics, with waterproofing in between, laminating them together.

Built-Up roof repair and maintenance can be completed by alternating layers of roof felts and bitumen. Therefore, forming a multi-layer barrier that will resist heat, wind, and water. BUR roofs are ideal for low slope surfaces and can also be installed over most roof decks as long as proper substrates are being used.

This consists of a rosin sheet base, wood, steel, concrete, and cement fiber. Multi-layered 2-Ply Built-Up Roofs are also usually compatible with all kinds of roof insulation of any density to provide long-term, energy-efficient waterproofing. Depending on climate, foot traffic, and the commercial roofing manufacturer materials used a BUR roof can last up to 30 years.

call us at!